It is vital to understand the paperweight while printing. The weight of the paper significantly affects the value of the print-related project. However, many people are confused by all the jargon related to printing. The right weight and thickness of paper bring the right outcomes. Thus, many designers are still learning new things. When it comes to paper, the stock, and thickness, there is certainly enough to know. Trust us, this is not a simple task. The paperweight theory comes under the pound measurement system is quirky. But you should learn the whole system. So, learn a few facts about printing in this guide.

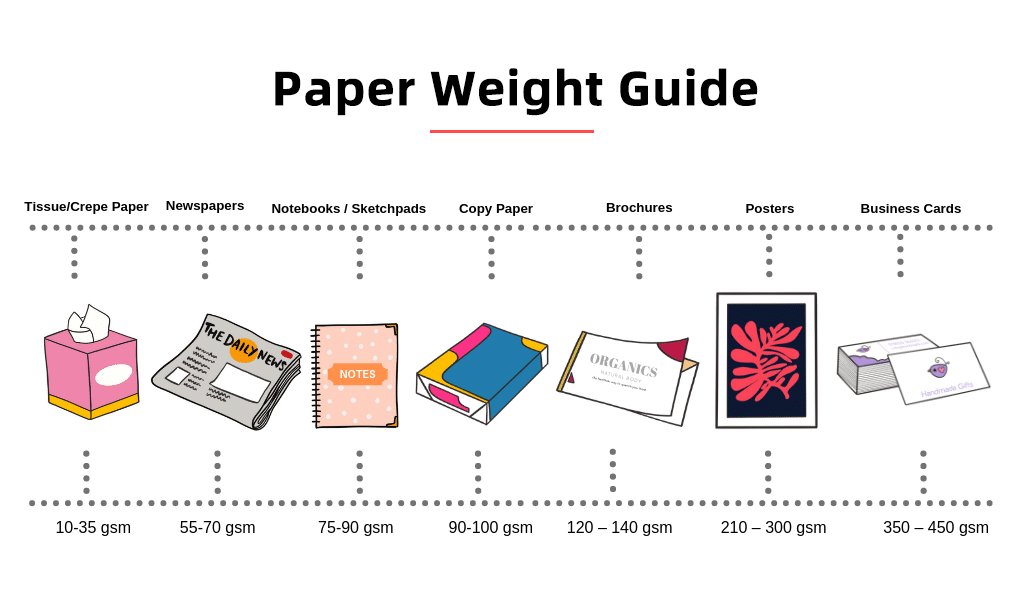

The paperweight typically means the weight of a sheet of paper. Typically, paper is measured in pounds or grams. It helps to measure the thickness and density of paper accurately. However, the GSM and lbs show the sturdiness of the paper. The overall quality is the feel of printed material measured by paperweight. Whether you print business cards, brochures, or packaging, the paperweight matters a lot. It affects the durability, functionality, and look of the boxes.

Every detail matters in the printing projects. Paperweight is also vital to change the brand’s perception. However, the printed paper works like a powerful marketing tool. It can change a simple piece of paper into a billboard. Thus, it makes an overall impression and leaves the audience stunned. Think about the business card. If you print flimsy cards, it may ruin your company’s image. In contrast, thicker cards feel reliable. It immediately makes a strong impression. That’s a big difference that paper can make. You should know How You Describe the Weight of Printing Paper. Keep in mind, that the quality paper aligns with your brand’s image. It boasts the first physical interaction with the consumers.

GSM stands for gram per square meter which is a measuring system. It helps to know the right weight of paper. Unlike the pound measurement, GSM is the best measurement to know the paper’s density. It brings more accurate thickness and weight of paper. Thus, the packaging designers also use the GSM method to get standard paper thickness. The higher GSM indicates the heavy and thick paper value. It could be the ideal choice to print high-end boxes and business cards. Instead, a lower GSM signifies the lighter and thinner paper. It is often used for printing and notebooks.

It is crucial to measure the paperweight accurately. The right weight of paper matters for personal and commercial projects. Thus, there are many methods to measure the paperweight. The GSM and basis weight are standard units of measurement.

This measuring method is usually used in the US. Basis weight comes in pounds of a quantity of paper (500 sheets. It measures in basic or uncut size. However, the basic weight depends on the basic size of the paper. This cut depends on different kinds of paper. Usually, the basic size is 17 17 x 22 inches.

GSM is the most used method globally. The single sheet of paper is 1 meter by 1 meter in GSM. However, this method is more consistent and simple. It is easier to compare different types of paper. So, a paper with GSM will be higher in quality.

The right paperweight will be gained after understanding the difference between measurements. Ensure to choose the right weight to gain the desired functionality and quality in printing material.

It is challenging to know the right paperweight. However, it is crucial to make a successful printing project. Thus, it is better to understand GSM and caliper to make well-informed decisions. Still have confusion and need further assistance, feel free to reach out to The Exact Packaging. With our professionals, you can make a successful printing project in no time.

Read More: What are pr Packages